To summarise the current situation, there are two mysteries:

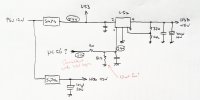

- Why the unit resets if 5V does not appear on the HDD power at the right time. This is unimportant, it just does.

- Why there is a runt signal on the enable (CTL) pin U52/1. This appears to be the crux of the matter, and the fact even a runt signal is able to turn the LDO on when there is no current demand (but not for higher current as is required with the load of an HDD) obscures the problem when just probing around with a meter. I think it's a property of the analogue (rather than digital) implementation of the device.

Thinking out loud: it is bothering me that the enable pin characteristics are only specified at zero load current. I presume the signal is supposed to be adequately buffered that the characteristics do not change significantly, so why not specify at a more useful load current (ie 1A)? If the pin

is adequately buffered, why is there a difference in behaviour between load and no load? When the input transistor will be off for an enable pin voltage less than 0.8V max, why does the LDO appear to turn on (no load) with a runt input of 0.6V?

My speculation is that the 'scope traces are wrong or being misinterpreted. I think I might have had a bad contact (hand-holding the probe onto the pin, or maybe the probe grounding). The 'scope's vertical scale is not obvious: I'm using 10x probes, and I'm not sure whether the scale factor shown on-screen is per division or full scale (will clarify that point using the calibration signal). Whatever, my conclusion (that a runt signal results in a low-drive output) does not, on second thoughts, appear likely – especially considering the enable pin input structure.

I shall repeat the measurements and confirm what's what. If it really is a runt signal, why? Either the input has gone low impedance (not very likely) or the drive is broken (which I presume to be a general purpose I/O pin on the SoC). I should be able to determine which by lifting the enable pin (tricky but doable).

If I find, as I suspect, the signal is not a runt and the error is in measurement, I'm back to pinning the blame on the LDO being bust, with the series pass element gone high impedance (able to pass some current, but not enough to drive the load). This seems the most likely scenario to me, by principle of Occam's Razor.